Changing from a paper process to input on a PDA with automatic wireless transmission to the main computer can dramatically boost worker productivity. Any process that involves collecting data using paper documents is potentially a candidate for a mobile solution to reduce data entry errors and speed up the reporting process.

In my crusade to simplify and PDA enable AX 2012 functionallity I have taken a look into production, and created some easy to use PDA forms.

Most manufactured items move through the production process sequentially. The sequence starts when a production order is created and ends when the product is ready for shipment. In Microsoft Dynamics AX, each sequential step is associated with a specific status. The status reflects where the item is in the production life cycle.

You can monitor the activities in each step of the production and move the production to the next status when you are ready. If you omit intervening steps when you change the status, the system automatically runs the necessary missed steps for you.

· Create – Status of the production order when it is created.

· Estimate – Status of the production order after you run a material and cost estimation.

· Scheduled – Status after you run operation or job scheduling.

· Release – Status when the production order is scheduled and has been released to production.

· Start – Status of the production order when production starts.

· Report as finished – Status of the production order when production is finished and ready for final action.

· End – Status of the production order after final costs have been applied, the item is complete, and the order is no longer active.

The PDA production covers the basic tasks for a production order centered on material and hour consumption. The PDA program will make it easier to register these transactions in environments where ordinary PC cannot operate.

The idea of the PDA production is to simplify the entry of consumption, and to report statuses. The main functionality is therefore centered on the following functions.

Start production

Start the production. This will also create the picking journal that will be used in production picking. Often the reservation of BOM-line is done when starting the production.

Report BOM Lines

Report material consumption according to the BOM picking journal.

Report Hours

Report hours on jobs and operations.

Report as Finished

Report finished goods as finished into a put-away location.

End production

End the production, and perform costing. Normally this is done in back-office.

The PDA production do not have any “create production”, because creating productions, BOM, delivery date and soon, is regarded as a back office function, and it requires more detailed information about sourcing to be sure that this is done correctly.

So the PDA production focuses on what is actually taken place on the production floor.

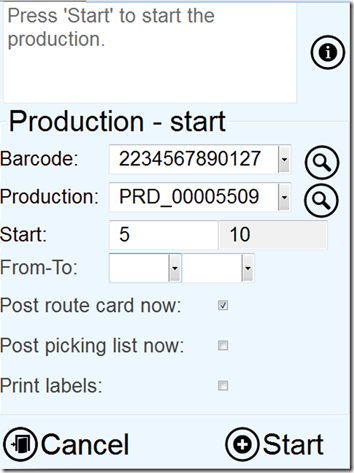

Start production

After a production order is started, you can post costs against the order. The system can be configured to estimate material and route costs that are allocated to the order when the order is started. This allocation is known as pre-flushing or auto consumption. You can manually allocate material to the order by creating picking list journals. You can also manually allocate labor and other route costs to the order. If you are using operations scheduling, you can allocate these costs by creating a route card journal. If you are using job scheduling, you can allocate these costs by creating a job card journal.

The start production will therefore let you perform this step.

Barcode:

Accepts item barcodes or EAN128 codes.

Lookup is filtered to only show item barcodes that has an open production order associated. View details will open the item information form. If only one production is found on the specific barcode, then the production will be auto-filled in.

Production:

This field accepts production numbers as input. Lookup is filtered to only show productions that is an open. View details will open a list view that shows the BOM-lines associated to the production.

Start:

Specify how many that should be started. This affects the creation of production picking lists and route/job cards. In the right field, show the remaining quantity to be started (scheduled quantity – started quantity)

From – To:

If only a subset of operations should be started, then specify the From-To operations here.

Post route card now:

Select the check box to automatically post the created route journal.

Post picking list now:

Select the check box to automatically post item consumption when the production is started. The program posts transactions in the picking list journal to the ledger. This pre-flushed the BOM consumption.

Print labels:

The print labels, will print item labels, when starting the production. This can be a good thing, especially, because the barcodes in on the labels can be placed on the product as they are being produced. The labels that will be used are labels associated with the production table in the Columbus BTI/Bartender module.

When done, press the start button to start the production order.

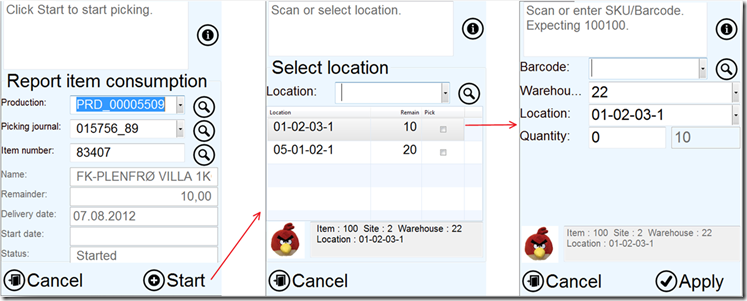

Report item consumption

Report item consumption is picking material to the production order. It is normally used to pick from the warehouse at the specified locations.

The first screen is where the production is identified. If labels where printed in the start production form, it is simply to just scan the production number. The production field also accepts scanning Item barcodes IF there are only one single open production order on the item barcode.

If there are only one open picking journal, then the PDA will fetch that picking journal identifier. The item number is just the item number of the produced item.

The rest of the fields are information fields showing item name, delivery reminder of the production, delivery date, start date and current status.

The next screen will show all the locations that should be visited to pick the picking journal lines. The PDA operator scans the location (Or push the “pick” checkmark) to pick the specified line. Then the third screen will appear where the operator can confirm the item barcode and even change inventory dimensions like location, serial, batch etc.

When the user clicks on “apply” the line is picked from the inventory, and consumed in the production order.

The last step is to finish the picking that will post the production picking journal. The finish of the production picking journal will change the status of the picked items to “Deduced”.

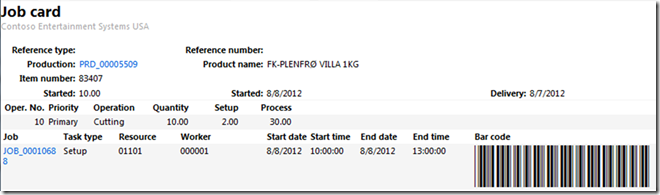

Report resources/Hours

The Columbus PDA can be used to report hour consumption in the production. Use of the PDA report resources is the same as using a route journal, and will report process and setup hours per operation.

The PDA screens consists of 3 screens, but if Job-ID scanning is used, than only 2 PDA screens is required.

In the first screen the user can identify what production order that we works on. The user can here also enter the operation ID, if this is known. The user can also scan the Job identifier directly to report hours. Dynamics AX 2012 do have out-of-the-box support for printing barcodes directly on the job card, as shown here:

If the user do not specify any operation or job-id, then the select operation screen will show when pressing start.

In the select operation, only the remaining operations will be shown, and the user can either enter the operation number, or click on the “pick” field.

In the third screen, the user can enter process hours, setup hours. The user can also report number of good and error units on this operation. If an operation is reported with error, then the error cause can be entered. If the operation is complete, then it is also possible to checkmark this. This will have an effect on resource reservations, and also the progress reporting. In the top, the user can also select another worker, if several workers uses the same PDA.

The registration screen is have a column showing the remaining hours/quantity in the gray fields, as shown here.

When posting the hours, a production route journal will be created and posted. In this way, the reported hours are close to real time. To correct any wrong postings, just create a journal manually, and reverse the transactions.

The PDA resource reporting is using exactly the same validations as the production journal.

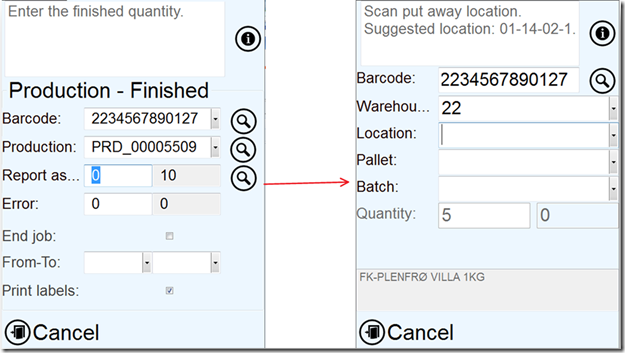

Report as finished

As the production progresses, items are finished. Then the PDA operator can perform a report as finished. The report as finished is therefore a put-away process. It is possible to also use the PDA arrival functionality, but the process shown here is optimized for production.

First the PDA operator identifies the production either by scanning the item barcode or production id. The item barcode field accepts production numbers. Then the operator enters the number of units to report as finished. The PDA will then ask for additional inventory dimensions, like location, pallet batch etc, depending on what is mandatory of the item to specify. The PDA will also suggest a put-away location.

Confirm the put away by clicking “apply”, and the items are then “registered” into the location.

The user can also report number of errors/failed products. And even limit the “from-to” operations, to just report as finished selected operation. The end job, means that all remaining jobs should be marked as ended.

The operator can also print labels here that can be useful if tracking dimensions like batch or serial numbers are used in the production process.

End production

The end production is the final step in the production process, and changes the receipt and issue transactions to “purchased/sold”. The costing details must still be fetched from the rich AX 2012 production form, but the actual ending can be done with the PDA.

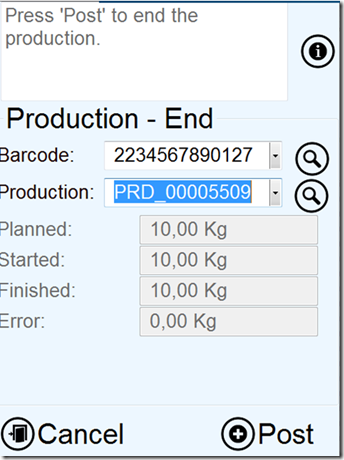

The Production end form on the PDA is very simple. It contains two input fields, and some quantity status fields.

If the user scans the item barcode, then the available productions order lookup will be filtered based on this. The lookup is also filtered on the current warehouse.

If there only exists one “reported as finished” production order, then this will automatically be select.

To end the production, just click post, and the production is ended.

Conclusion

With the Columbus PDA, it is possible to PDA enable your production, and take benefit of the realtime production process. A lot of readers of this blog has asked if this PDA solution is available, and the answer to this is yes, but only for AX 2012 RTM and Feature pack. Just contact us![]()

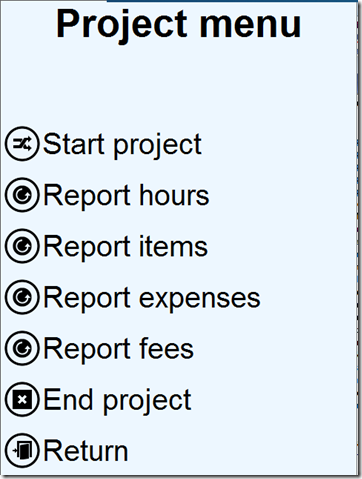

My next PDA project will be …….. project ![]() . Here is a silent preview:

. Here is a silent preview:

Stay tuned, and happy DAXing.

Hi Kurt, I have a few doubts regarding this product. We need a mobile solution for WMS processes. Please guide.

1) I looked at the Columbus site, but I couldn’t locate this product. Is it your project Columbus markets? Can you forward me the link to this product on the Columbus site?

2) This looks like it works through RDP. Would you really recommend such a solution? I believe it will have a performance lag.

3) This is actually operating AX on a PDA. So the steps remain the same – just that you can walk around while doing this. Will this add efficiency to the user experience?

4) Can you modify the user experience without doing AX customizations? Is there a framework where you can change the screens without modifying AX?

Thanks

Sagar Pokharkar

LikeLike

Hi Sagar

The Columbus PDA has been rebranded to DCS. You can find more information here https://www.to-increase.com/news/2013_new-scs-and-dcs-release.aspx and https://www.to-increase.com/cross-industry-solutions/supply-chain-solutions/data-collection-2014.aspx. The DCS is now available to all partners of Microsoft Dynamics AX through To-Increase. You may also contact sales@to-increase.com.

In relation to your concerns, we have not experienced any issues with RDP on our 20 customers currently running DCS. We even have customers with 500 handheld devices. As long as the infrastructure is dimensioned accordingly. We recommend 60-70 Devices per RDP server.

The feedback we get from customers, is that DCS is very fast and efficient. The DCS do not add new features for warehouse management processes, but rely on what is possible to do in std. AX. Our experience is that this is what the marked wants. You can also take a look at the available 54 processes here : https://www.youtube.com/user/DAX2012WMS/videos

The DCS is also created with a zero footprint in std. So you can do changes to DCS objects without customizing objects that originates from std. AX. But yes, you do use the Roles, security, AOT, X++ etc to make customizations and changes.

My suggestion is that you contact To-Increase to get a demo. Maybe this can give you the answers you need to go forward.

LikeLike