It has been a long time since I last had the chance to write about the WM&D. But now a major release is ready. The last months there has been a lot of implementations, and it is greate to see the positive response we get from the customers. The WM&D is now setting focus on adding WMS and distribution value to the new Dynamics AX for retail, that Microsoft is launching in august.

To support different distribution scenario, the WM&D is now offered in 3 different editions.

Standard edition – is a value offer to small to medium enterprises, and focuses on the traditional processes like receive, picking packing and shipping.

Professional edition – is used for every day distribution centers, and is extended with support of cross-docking, license plates, kitting and VAS.

Enterprise edition – is multi site distribution centers that often have yard management, mini load, conveyor systems, transportation planning and EDI integrations for both inbound and outbound.

More details of the different editions is available on the To-Increase partner portal, or contact your Partner Account manager.

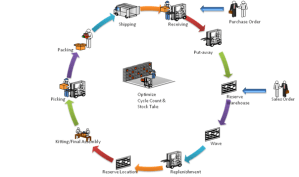

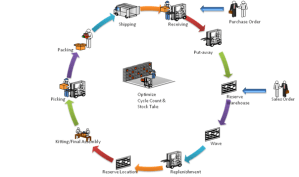

The main theme for the R2 has been to give users of WM&D a full featured WMS system. The basic processes can be visualized like this. With the introduction of Kitting and VAS, the full circle is complete.

In the R2 release the WM&D has been extended with Danish language, and WM&D is now supported with all English, Norwegian and Danish. In addition Spanish demo language has been created. Other languages will be available on request.

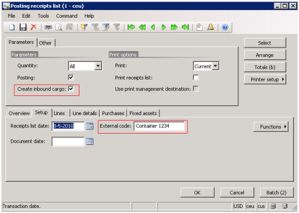

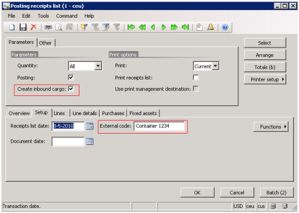

To better support the use of inbound cargos, the receipt list posting, has been extended so inbound cargo’s can be created when manually posting a receipt list. In R1, this process was only supported when the Advanced shipping notification (ASN) was received through AIF/BizTalk.

This makes it easier following up inbound for companies that have not a full EDI integration to vendors and carriers. This feature is now available in the professional edition.

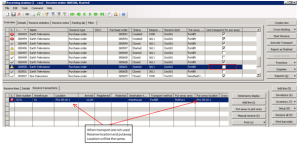

Receive station has been extended to support a better suggestion for locations, when internal transport are not used. The receive station will now search for locations first in buffer area, and then in the pick area. This simplifies the use of receive stations in scenarios where PDA/RF devices are not in use.

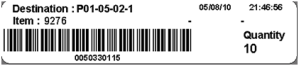

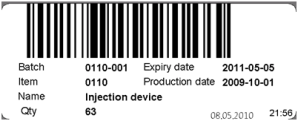

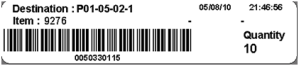

From the receive station it is now possible to print put away labels that can be scanned by PDA.

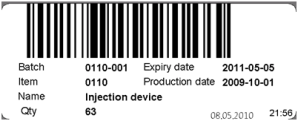

From the receive station it is now possible to print batch labels that can be scanned by PDA in later process

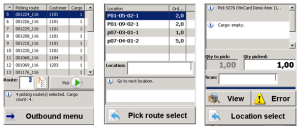

With WM&D R2 the Pick->Pack->Stage->Load->Ship process has been improved, and additional screens for staging has been introduced.

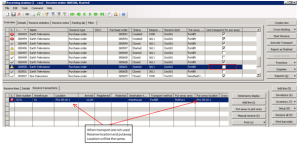

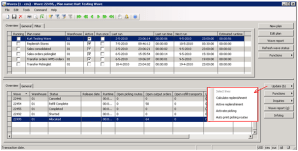

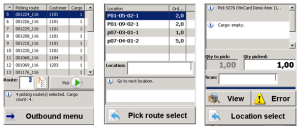

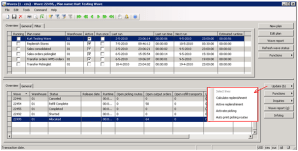

In R1, the creation of waves was very automated. A new wave overview has been created to give better insight and steps involved in a wave planning scenario.

Users can now manually select, calculate replenishment, activate replenishment, activate picking, and print/release picking list for each wave.

Functions for wave merge and wave shortening has been introduced.

Kitting offers companies that are not equipped with finished goods warehouse facilities or cannot afford the capital expenditure of setting up a finished goods warehousing facility. Your company can take advantage of the services that are necessary to forward a product to market quickly. Kitting involves the assembly of products in boxes, shrink-wrap, blister, or clamshell packaging.

Some companies require assistance preparing their product for shipment and display. There is a better chance of selling your product if it is accurately packaged and prepared for market. There is nothing worse than excitedly opening a new item just to find that pieces are missing from the package.

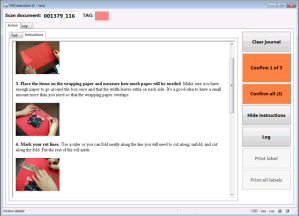

Just an example of how this process may work: You have several items that belong together in a package. In an assembly line, each individual in the line subsequently adds another component to the package in a specific order. This ensures that everything is included in the package. At the end of the assembly line, an individual conducts a quality review. Part of that review could include weighing the package. If the weight of the package is accurate, then all the parts have been included; no more no less. If the weight is incorrect even by a couple of ounces, then it means that either a component is missing or there is an additional part.

Kitting allows the warehouse to build an order for shipping then distribute or store it. Getting the distribution center to kit your products not only prepares the items for distribution, but may also save your company money, because you do not have the labor costs and capital expenditures to deal with.

2.6.2 Real time wave processing

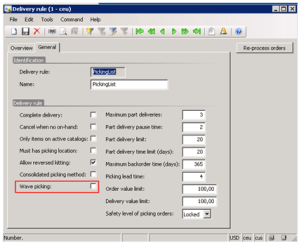

In R2, a real time wave processing is available. As soon as an order is confirmed, the order processor can automatically release replenishments and activate picking lists. This is well suited for same-day delivery scenarios.

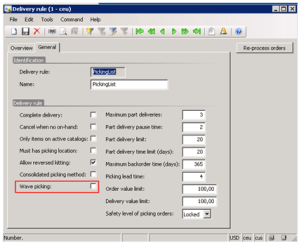

By removing the “wave-picking” check box, the system will do real time order processing and replenishment.

Batch picking is a process where multiple orders are picked simultaneously, and it is used to reduce transit time. With a “man to goods” system where an order selector travels to the product to fill orders, batch picking can drastically reduce the travel time. In a “goods to man” system where product is delivered to the selector, batch picking can reduce delivery traffic.

Batch picking is only available when using handheld PDA’s

Zone picking has been introduces, so that WM&D creates one picking route per pick area.

2.7.3 Value added services (VAS)

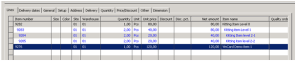

A new value added service solution has been created to support VAS functionality. We define VAS as a set of actions, associated costs, expenses and additional items that we want to be logically bundled in order to be easily and logically presented to a stakeholder (a sales processor, warehouse worker or end customer).

VAS is an atomic item, having a specific VAS type that can be

a) Item. An item that exist in the sales order.

b) Cost. A cost associated with VAS, which corresponds to a misc charge on the sales order. There will be also a functionality relating a cost code that is an attribute of VAS line, to a set of misc charges that will automatically be added to the sales order whenever VAS line of type Cost is included.

c) Service. A service that is associated with a service sales line.

d) Action – a set of instructions to a warehouse worker with the guide of what and how to do in relation to the VAS.

e) Package. Used to specify that some set of items needs to be packed together.

f) Labeling

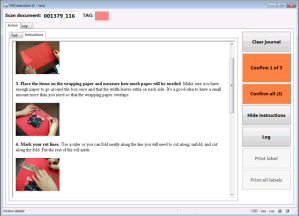

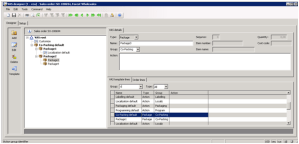

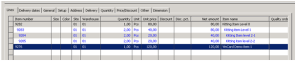

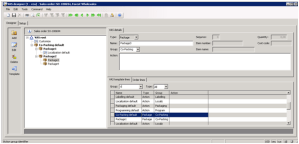

A VAS designer let’s you define the VAS services that must be applied to a salesorder.

The effect of this is the VAS execution that confirms every VAS step needed.